|

|

|

|

|

|

|

|

|

HOME / Technology / FINE BLANKING |

|

|

|

|

|

|

|

|

|

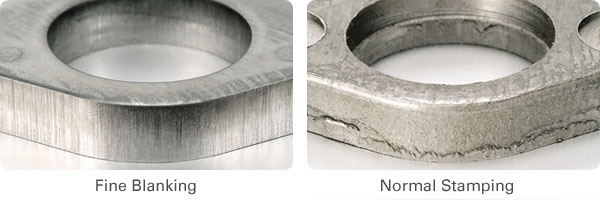

FINE BLANKING technology is a press manufacturing process to get accuracy of products and fine cut section which is required for the whole production through one process of blanking.

In here, the word ‘FINE’ means getting precise and excellent surface. Per BLANKING is a process of cutting to get a product, the cut section does not need machine work anymore.

For it’s specialty, FINE BLANKING technology is applied on products with thickness of 5 ~ 15cm that has no economical efficiency per increase of repeating processes at regular press blanking for purpose of use. So, FINE BLANKING products are objects for parts that require accuracy of product and quality of surface such as parts for car, compressor part of refrigerator, electrical or electronic structural parts, and essential parts of general machines.

FINE BLANKING can be used for flat product, bending, Offset banding, coining which presses patterns or shape on the surface of product, plasticity processing such extrusion processing that projecting the other side by pressing material for assembly without harming accuracy.

|

|

|

|

|

|

|

|

|

|

|

#58-17, SEONGSAN-DONG, CHANGWON-CITY GYEONGNAM, KOREA

Phone 055 - 289 - 4883 ~ 9 l Fax 055 - 289 - 4890

email to fb@dsfinetec.com l DAESUNG FINE TEC CO., LTD. All rights reserved. |

|

|

|

|

|

|

|

|

|

|

|

|